רגישות ללא עומס: שחררו בעדינות את הכפתור כדי להוריד את קורת האיזון, רשמו את נקודת האפס של המאזן, ולאחר מכן סגרו את הכפתור כדי להרים את קורת האיזון. השתמשו בפינצטה כדי לקחת קוד סליל 10 מ"ג ולהניח אותו במרכז החלק השמאלי של המאזן. שחררו את הכפתור שוב, לאחר שהמצביע יציב (יציב וללא שינוי), קראו את קריאת נקודת האיזון, סגרו את הכפתור וחשבו את רגישות הדיסק הריק (רשת קטנה/מ"ג) ואת הרגישות (מ"ג/רשת קטנה) מההפרש בין נקודת האיזון לנקודת האפס.

Ⅰ. בדיקת מראה:

1. הורידו את מכסה המאזן, ערמו אותו והניחו אותו במיקום המתאים, ובדקו את המשקל. האם המשקולות בקופסה שלמות, האם הפינצטה להידוק ה...משקולותנמצאות בקופסה, האם משקולות הטבעת שלמות ותלויות כראוי על וו הטבעת, והאם קריאת דיסק הקריאה היא אפס.

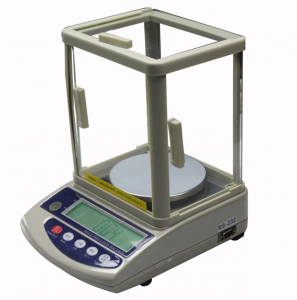

2. אם יש אבק או חפצים אחרים הנופלים על משטח המשקל, יש לנקות אותו בעזרת מברשת רכה. משקל אנליטי הוא מכשיר לשקילה מדויקת של מסה מסוימת של חומר. לפני השקילה, יש לבדוק האם המאזן תקין, האם הוא במצב אופקי, האם זיזי ההרמה ומשקולות הטבעת נופלות, והאם החלק הפנימי והחיצוני של מסגרת הזכוכית נקיים.

3. בדקו האם המאזניים במצב מנוחה והאם מיקום קורת האיזון וציר ההרמה תקין. מאזניים אלקטרוניים משמשים לשקילת עצמים. מאזניים אלקטרוניים משתמשים בדרך כלל בחיישן מאמץ, חיישני קיבול וחיישני איזון אלקטרומגנטיים. לחיישן מאמץ מבנה פשוט, עלות נמוכה אך דיוק מוגבל.

5בדקו האם המשקל נמצא במצב אופקי. אם לא, כוונו את שני ברגי הכוונון האופקיים בבסיס הרגל מתחת לחזית המשקל כדי ליצור בועות בפלס הבועות במרכז.

Ⅱ. רגישות: רגישות המאזניים היא מספר קטן של רשתות המוסטות בין נקודת האפס של המאזניים לנקודת העצירה, הנגרמות עקב עלייה של 1 מ"ג במשקל. ככל שהמאזניים רגישות יותר, כך הסטת הרשתות גדולה יותר. הרגישות מתבטאת בדרך כלל ברגישות, המתייחסת לאיכות הנדרשת כאשר המצביע מוזז ברשת אחת.

Ⅲ. כוונון אפס: נקודת האפס של המאזניים מתייחסת לנקודת האיזון כאשר המאזניים פרקו. יש למדוד את נקודת האפס של המאזניים לפני כל שקילה. מאזניים אלקטרוניים משמשים לשקילת עצמים. מאזניים אלקטרוניים משתמשים בדרך כלל בחיישן מאמץ, חיישן קיבול וחיישן איזון אלקטרומגנטי. לחיישן המאמץ מבנה פשוט, עלות נמוכה, אך דיוק מוגבל. לאחר השלמת בדיקת מראה המאזניים, הפעילו את ספק הכוח וסובבו את כפתור ההרמה עם כיוון השעון עד הסוף (הפעל את המאזניים). בשלב זה, ניתן לראות שהקרנת המשקל המיניאטורי נעה על מסך האור. כאשר המשקל מצביע על כך שהחלקים המשמשים לציון השעה המתאימה בשעון יציבים (יציבים; ללא שינוי), אם קו המשקל על מסך האור אינו תואם את קו 0.00 של המשקל, ניתן לסובב את מוט כוונון האפס שמתחת לכפתור ההרמה כדי להזיז את מסך האור כך שיתאים, ונקודת האפס תותאם. אם מסך האור זז עד הסוף ועדיין אינו יכול להתאימו לקו 0.00 של הסרגל, אנא...rסובב את בורג האיזון על קורת האיזון כדי לכוון.

זמן פרסום: 21 באוקטובר 2022